Sipping the future: MyAppCafé offers fully automated robot baristas

“We wanted a real industrial robot, not a “toy”. And Kawasaki was very accommodating as a partner and with the quality of the robots”

Michael Stille, CEO at MyAppCafé

Order Your Coffee on the Go from a Robot Barista

Airports can often have stressful environments.

At the Cologne/Bonn Airport, there is a convenient way to enjoy a calming cup of coffee amidst the chaos.

Order your preferred cup of coffee via app while on the bus, scan the QR code, and let a robot barista serve it fresh as you arrive.

This was made possible with MyAppCafé in collaboration with Kawasaki Robotics.

MyAppCafé provides over 160 coffee specialties, ready to serve with your custom design of foam, ensuring you have a cup of coffee for your further travels.

The Journey to Find the Perfect Robot

The concept of a robot barista came to MyAppCafé CEO, Michael Stille, while watching an episode of “Tatort,” a German police series featuring a catering robot.

This inspiration led to the idea of providing fully automated barista services in busy areas such as airports, shopping centers, train stations, and hospitals.

The search for a robot provider began, and initial conversations revealed a similar solution existed in the USA but without interest in the European market.

Collaboration with two other Karlsruhe companies, IBS and Rothweiler Feinwerkmechanik, brought this innovative idea to life.

The Heart of the Cell is A Robot

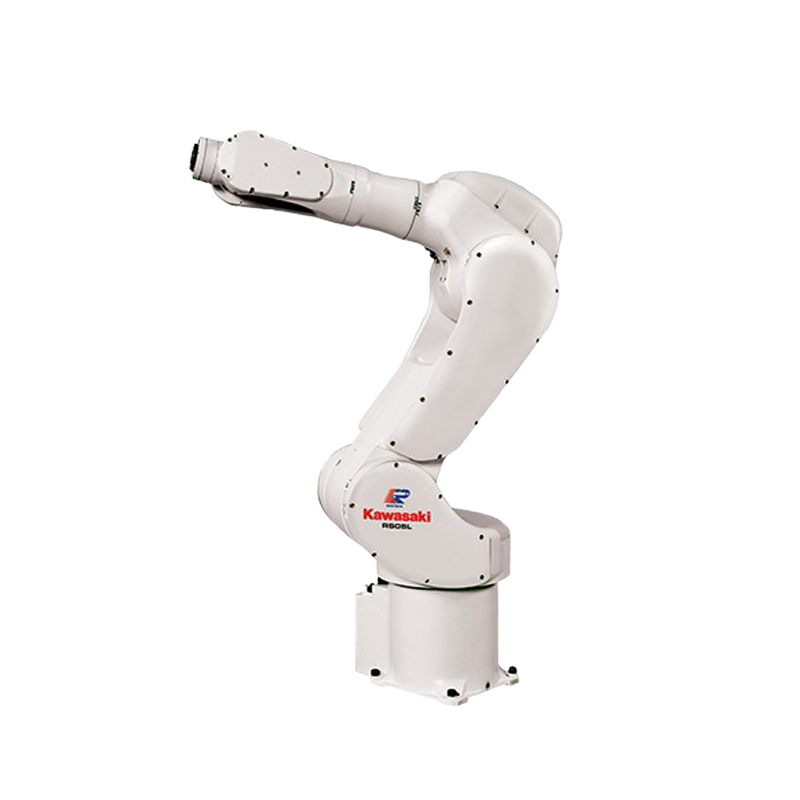

After reviewing and comparing several robot options, the choice quickly settled on the Kawasaki Robotics RS005L.

The engineering office, IBS, has been a close partner of Kawasaki Robotics for many years, making the choice unquestionable.

With a maximum payload of 5 kg and a maximum reach of 903 mm, the RS005L is part of the universal R series for small to medium payloads, suitable for assembly, material handling, machine tending, and many other applications.

Its special design enables the high-speed robot to have a longer reach and an extended working range.

Beyond its technical capabilities, the RS005L impressed Michael Stille with its appearance, which seamlessly integrated into the design of the cell:

“We wanted to have a real industrial robot inside, not a “toy”. And Kawasaki Robotics was very accommodating to us as a partner and through the quality of the robots”.

A Robot Barista Was Created with Rapid Success

With the manufacturer of the robot chosen, the creation of the actual cell began.

Covering approximately 7 square meters, the cell slowly came to life according to Silence’s detailed vision.

Through business and technology networks in Karlsruhe, the right experts were brought in for all components.

The startup, ROCK5, from Karlsruhe developed the intuitive app.

Within a few months, this development led to a successful prototype meeting the high demands for full automation, intuitive operation, and reliability.

Just in time for the Franchise Expo in Frankfurt am Main, the MyAppCafé cell was ready to be presented to the market. It debuted in November 2019, achieving great success and generating numerous inquiries.

Soon after, MyAppCafé found an optimal location at the Postgalerie in Karlsruhe, making it accessible for tests and presentations.

Two MyAppCafé coffee machines are available for travelers in Terminal 2 at the Cologne/Bonn Airport, one in the public area and one at the baggage claim. It is also placed in shopping centers in Heilbronn, Hamburg, Berlin, and Vienna, as well as airports and train stations across Europe.

Two machines can also be found in the USA, impressing patients, staff, and visitors at Ohio State University’s Wexner Medical Center and Akron Children’s Hospital.

High Economic Efficiency, Optimized Cleaning Processes, and Minimum Personnel Costs

The primary goal during the development of the robot barista was cost-effectiveness.

Each franchisee spends a maximum of one hour a day on refilling and maintenance, with the rest being fully automated.

The MyAppCafé system only needs refilling after approximately 650 servings. The system notifies operators just in time to prevent unnecessary downtime.

Michael Stille emphasizes the benefits of this fully automated gastronomy solution

“Almost no personnel is required, a maximum of one hour of working time for refilling and cleaning must be scheduled efter 650 issues. By comparison, four employees would be needed to provide the same service. With our robot barista, you are in the profit zone much faster.”

Moreover the integrated automatic cleaning system combine the highest form of hygiene standards with just minimum effort.

A Cup of Coffee Is Just One Click Away

Ordering coffee has never been easier.

Simply use the app or the touchscreen at the cell to select your coffee specialty.

The Kawasaki robot takes a cup and transports it to one of the two high-end WMF 9000 S+ coffee machines, as well as to the syrup stations and the specially developed milk system if needed.

The robot then moves to a dispensing station where you can pick up your freshly prepared coffee. This efficient robot can prepare and serve up to 120 cups of coffee per hour.

Want your coffee to be special? MyAppCafé allows you to decorate your hot drinks with custom text or pictures on the milk foam using a food printer, at no extra cost.

You can even upload your own photos via the app and have them displayed on a fresh cup of cappuccino.

The barista is available 24 hours a day, seven days a week – no waiting, no queues. Payments are easy and contactless with EC cards, credit cards, PayPal, Apple Pay, and Google Pay.

All cups and lids are made from environmentally friendly and compostable corn starch. Additionally, all ingredients have organic and fair-trade seals — from the coffee to the optional soy milk.

This commitment to sustainability was a priority for MyAppCafé from the start.

To contact Kawasaki Robotics EMEA for further questions or inquiries:

Marc Kluge, sales@kawasakirobotics.de